Differences Between Virgin and Recycled Methyl Methacrylate ( MMA ) : Recovery Process, Reuse Applications, Environmental and Economic Benefits, Challenges and Future Outlook

Methyl methacrylate (MMA) is renowned for its outstanding chemical properties and broad applications in acrylic products, optical films, adhesives, and more. With growing environmental awareness and limited resources, recycled MMA (r-MMA) has become a crucial trend in modern manufacturing. This article explores the differences between recycled and virgin MMA, detailing the recycling process, environmental benefits, and economic value.

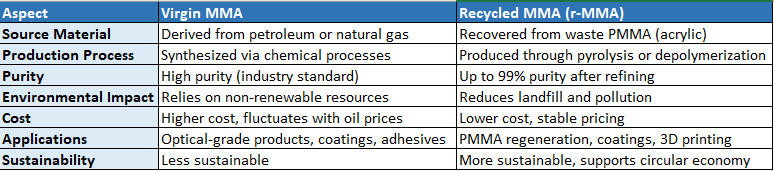

1. Virgin MMA vs. Recycled MMA (r-MMA)

Virgin Methyl Methacrylate (MMA)

MMA is a clear, colorless, and highly volatile synthetic chemical derived from petroleum or natural gas. It’s used in manufacturing acrylic sheets, tissue preservatives, adhesives, latex paints, and more, thanks to its excellent transparency, weather resistance, and durability.

Further Reading : What is Methyl Methacrylate (MMA)? Hazard Classification, Uses, Risks, and Storage Guidelines

r-MMA is typically extracted from waste poly(methyl methacrylate) (PMMA), also known as “acrylic.”

Key differences between the two include source material, purity, and cost-effectiveness, with recycled MMA offering a more sustainable option for many applications.

2. r-MMA Recycling Process

(1) Waste Collection and Pre-treatment

- Collect waste acrylic (PMMA) materials, including discarded acrylic sheets, transparent plastic boards, optical components, automotive light covers, etc.

- Crush into smaller particles or fragments, then clean to remove impurities (oil stains, dust, etc.).

- Analyze feedstock to determine suitable processing method (thermal or chemical cracking).

(2) Decomposition Methods

- Pyrolysis: PMMA is decomposed into MMA monomer in an oxygen-free, high-temperature environment, followed by condensation and separation to obtain pure MMA.

- Depolymerization: Using catalysts, PMMA is chemically broken back down into MMA monomers.

(3) Purification and Refinement

- Process Optimization: Advanced catalysts and distillation techniques remove water and by-products. Current technologies can achieve up to 99% purity, sufficient for most applications.

- Additives: Improve impact resistance and durability using rubber modifiers or antioxidants.

- Blending: Mix with virgin MMA or high-performance resins to enhance performance.

- Deodorization and Color Removal: Chemical treatments eliminate odor and color impurities to improve clarity and appearance.

3. Reuse Applications of r-MMA

- High-End Uses (Optical & Electronic Materials): Highly purified r-MMA can be used to produce optical-grade PMMA for lenses and display panels.

- General PMMA Production: r-MMA can be repolymerized into PMMA used in construction, signage, automotive parts, etc., with comparable transparency and mechanical properties to virgin PMMA.

- Coatings: r-MMA can be used as raw material for acrylic coatings, such as building and floor paints. However, virgin MMA is more suitable for high-performance adhesives and coatings.

- 3D Printing: With proper treatment, r-MMA can be used as a base material for transparent or high-strength 3D-printed components.

4. Environmental and Economic Benefits of r-MMA

- Circular Economy: Promotes resource recycling, reduces reliance on petrochemical materials, and drives innovation across industries.

- Environmental Benefits: Since MMA is a plastic that does not decompose naturally, recycling reduces landfill and incineration, thereby minimizing environmental pollution.

- Cost Efficiency: Recycled MMA significantly reduces raw material costs and dependence on virgin MMA. Especially when petrochemical prices are volatile, r-MMA provides a stable and economical alternative. Additionally, many governments offer tax credits and subsidies for using recycled materials and reducing carbon emissions, further enhancing its economic appeal.

5. Challenges and Future Outlook for r-MMA

The recycling of MMA still faces technical limitations, especially in depolymerization processes that require specific conditions. Purity and consistency of r-MMA are affected by the quality of the waste materials. Improving efficiency and quality control is a key challenge.

However, with stricter environmental regulations and increasing demand for sustainable products, r-MMA holds tremendous potential. Future developments may include energy-efficient systems, automation, and closed-loop production models, driving even greater economic and environmental value for the industry.

Published Date: January 14, 2025