Understanding the Loading / Discharging and Air Valves of T11 ISO TANK : A Complete Guide to Using Adapters for Fast Loading and Unloading

ISO TANK T11 is commonly used for transporting chemicals. The connectors for its loading/discharging and air valves must match the factory or warehouse pipeline sizes to ensure a proper fit. This guide helps you understand the structure of ISO TANK T11 adapters and teaches you how to use them correctly.

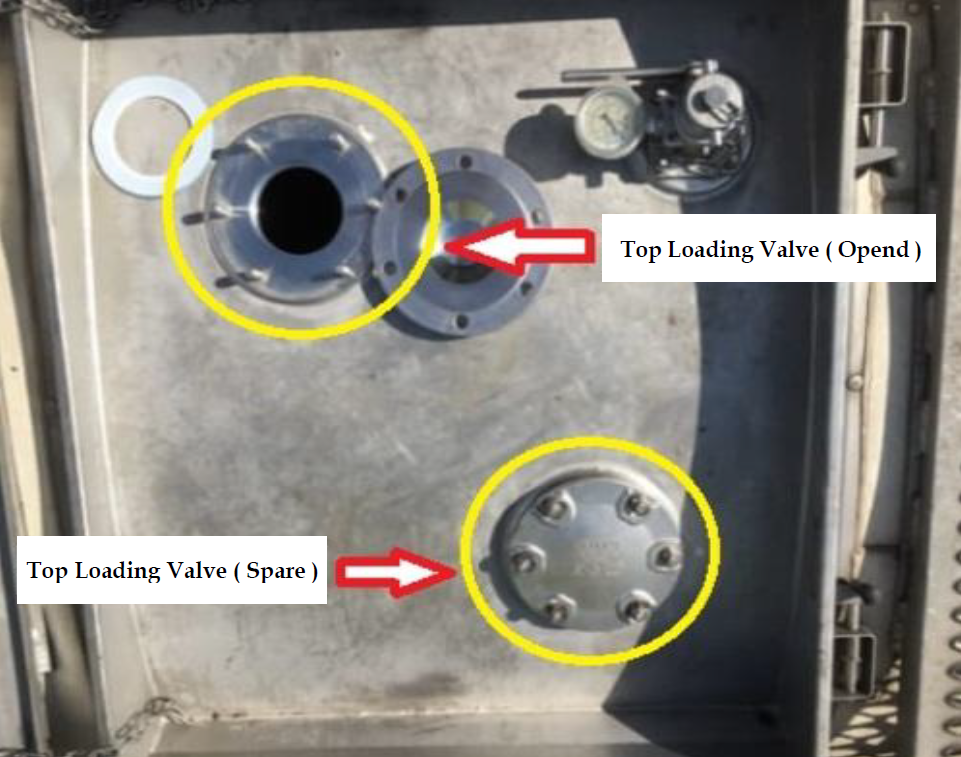

1. Top Loading Valve of ISO TANK T11 : Specifications & How to Install a Quick Coupling

The top loading valve is located at the top of the ISO TANK, sized at 3 inches (DN80). Before loading, the blind flange must be removed, and the pipeline must be connected. Ensure you confirm the connection size at your factory or warehouse and select a matching quick coupling. Below are the adapter components, connection sequence, and key precautions.

(1) Adapter Components (4-bolt or 6-bolt blind flange options)

- Size : DN80

- Pressure Rating : PN10

- Thread Type : 6-bolt flange (external thread)

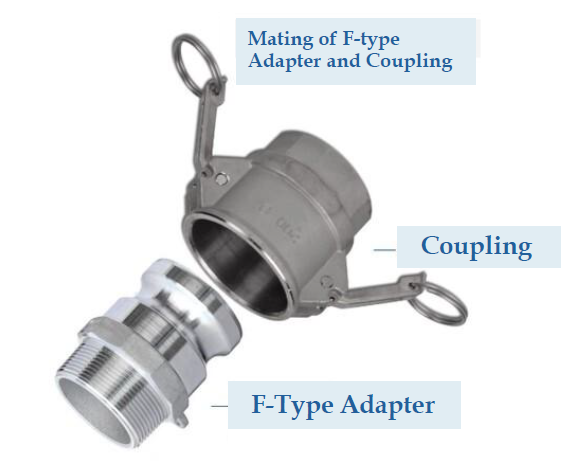

- Adapter : Connects the base of the loading valve to an F-type male-threaded coupling.

- Flange Gasket : DN80, spec: ISO PN10/40. Placed between the 6-bolt flange and F-type adapter to ensure air-tightness and prevent leakage.

- F-Type Adapter (3″ male thread) : Connects the DN80 PN10 flange to a 3-inch camlock quick coupling.

- 3″ Camlock Quick Coupling :

- B-Type (male thread)

-

- D-Type (female thread)

Choose based on whether the pipeline at the factory/warehouse uses male or female threads.

(2) Connection Sequence :

DN80 PN10 6-bolt flange → Flange Gasket DN80 ISO PN10/40 → F-Type Adapter (3″ male thread) → 3″ Camlock Quick Coupling (B-type or D-type)

(3) Precautions :

- Thread Type: Ensure that the F-type adapter and quick coupling have the same thread type. ISO TANKs use BSP (British Standard Pipe) threads.

- Leak Prevention: Gaskets must be used at all connection points, and all joints must be tightly secured.

- Material: Typically 304 or 316 stainless steel. Type 316 offers better corrosion resistance against strong acids/alkalis.

- Available Sizes: 1/4″, 1/2″, 3/4″, 1″, 2″, 3″, 4″, 6″

2. Bottom Discharge Valve of ISO TANK T11: Specifications & How to Install a Quick Coupling

The bottom valve is located at the bottom of the ISO TANK, sized at 3 inches (DN80) with BSP male threads. Before discharging, remove the valve cap and connect the pipeline. Confirm the size at your destination and select a suitable coupling.

(1) Adapter Components :

- A-Type Adapter (3″ female thread): Connects the bottom valve to a 3″ camlock quick coupling.

- 3″ Camlock Quick Coupling :

- B-Type (male thread)

-

- D-Type (female thread)

Choose based on the pipeline thread type.

(2) Connection Sequence :

Bottom Valve → A-Type Adapter (3″ female thread) → 3″ Camlock Quick Coupling (B-type or D-type)

(3) Precautions :

- Thread Type : Use matching BSP threads.

- Leak Prevention : Insert proper-size gaskets and ensure tight connections.

- Material : 304 or 316 stainless steel, depending on corrosion resistance needs.

- Available Sizes : 1/4″, 1/2″, 3/4″, 1″, 2″, 3″, 4″, 6″

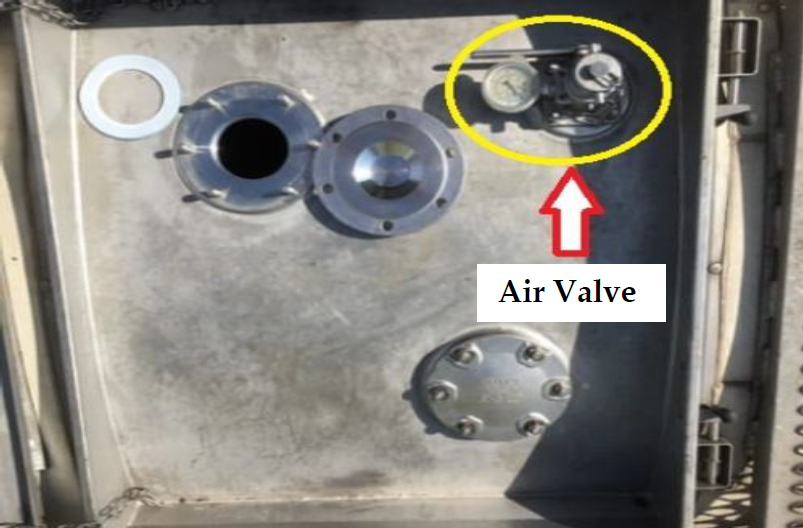

3. Air Valve of ISO TANK T11: Specifications & How to Install a Quick Coupling

The air valve is mounted on the top of the ISO TANK and sized at 1.5 inches (DN40). Before injecting air or nitrogen, remove the cover and attach the hose. As always, ensure compatibility with factory/warehouse connectors.

(1) Adapter Components :

- A-Type Adapter (1.5″ female thread) : Connects the air valve to a 1.5″ camlock quick coupling.

- 1.5″ Camlock Quick Coupling :

- B-Type (male thread)

-

- D-Type (female thread)

Choose according to the thread type of the destination pipeline.

(2) Connection Sequence :

Air Valve → A-Type Adapter (1.5″ female thread) → 1.5″ Camlock Quick Coupling (B-type or D-type)

(3) Precautions :

- Thread Type : Use consistent BSP threads throughout.

- Leak Prevention : Use matching gaskets and secure all joints firmly.

- Material : Choose between 304 or 316 stainless steel based on your cargo’s chemical properties.

- Available Sizes : 1/4″, 1/2″, 3/4″, 1″, 2″, 3″, 4″, 6″

Published Date : January 23, 2025