Understanding the Loading / Discharging and Air Valves of T14 ISO TANK : A Complete Guide to Using Adapters for Fast Loading and Unloading

ISO TANK T14 is primarily used to transport chemicals. To load or unload these tanks, the correct adapters must be selected based on the pipeline connections at your factory or warehouse. This guide walks you through the specifications of ISO TANK T14 valves and how to properly use adapters to ensure operational safety.

1. ISO TANK T14 Loading/Unloading Valve: Specs and Adapter Installation

ISO TANK T14 is designed for top-loading and top-unloading only—there is no bottom valve. The loading/unloading valve is installed on the top and measures 3 inches (DN80). Before use, the blind plate must be removed so pipelines can be connected for chemical loading or unloading. It’s crucial to match your factory or warehouse connections to the correct quick adapter. Normally sealed with a blind plate, which should be removed before use.

Closed valve Opened valve

(1) Adapter Components (For valves with 4-bolt flanges)

- Flange Adapter :

- Size: DN80

- Pressure: PN10

- Type: 4-bolt threaded flange

- Function: Connects the base of the loading valve to the F-type adapter

- Flange Gasket :

- Size: DN80

- Spec: ISO PN10/40

- Function: Inserted between the flange and F-type adapter to improve air-tightness and prevent leakage.

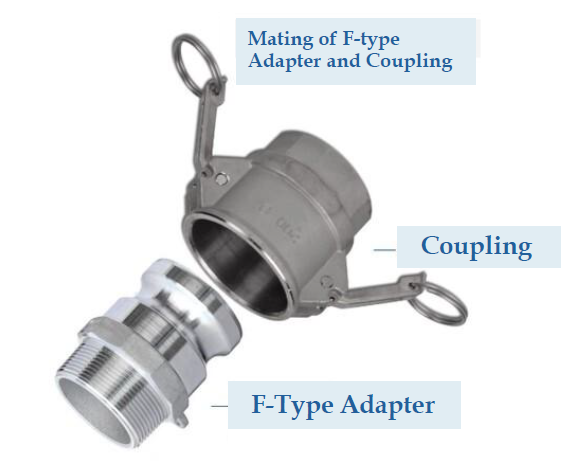

- F-Type Adapter (3″ Male Thread) :

- Connects the flange to the 3-inch quick coupling

- Also known as “male thread” or “external thread”

- 3″ Quick Coupling :

- B-Type : Male thread (external)

- D-Type : Female thread (internal)

- Choose the type based on the thread type of the factory/warehouse pipe :

- Use B-Type if their pipe has female threads

- Use D-Type if their pipe has male threads

- Principle : Male thread connects to female thread

3″ B-Type Coupling

3″ D-Type Coupling

(2) Connection Order

- DN80 PN10 Flange

- DN80 ISO PN10/40 Gasket

- F-Type Adapter (3″ Male Thread)

- 3″ Quick Coupling (B-Type or D-Type)

(3) Key Considerations

- Thread Compatibility : Ensure that the threads on the F-type adapter and the quick coupling match. ISO TANKs typically use BSP (British Standard Pipe) threads.

- Leak Prevention : Use appropriate gaskets between all connections. Ensure a tight seal between adapter and coupling.

- Material : Most parts are made from 304 or 316 stainless steel. 316 offers higher corrosion resistance—ideal for strong acids and alkalis.

- Coupling Sizes : Available in 1/4″, 1/2″, 3/4″, 1″, 2″, 3″, 4″, and 6″.

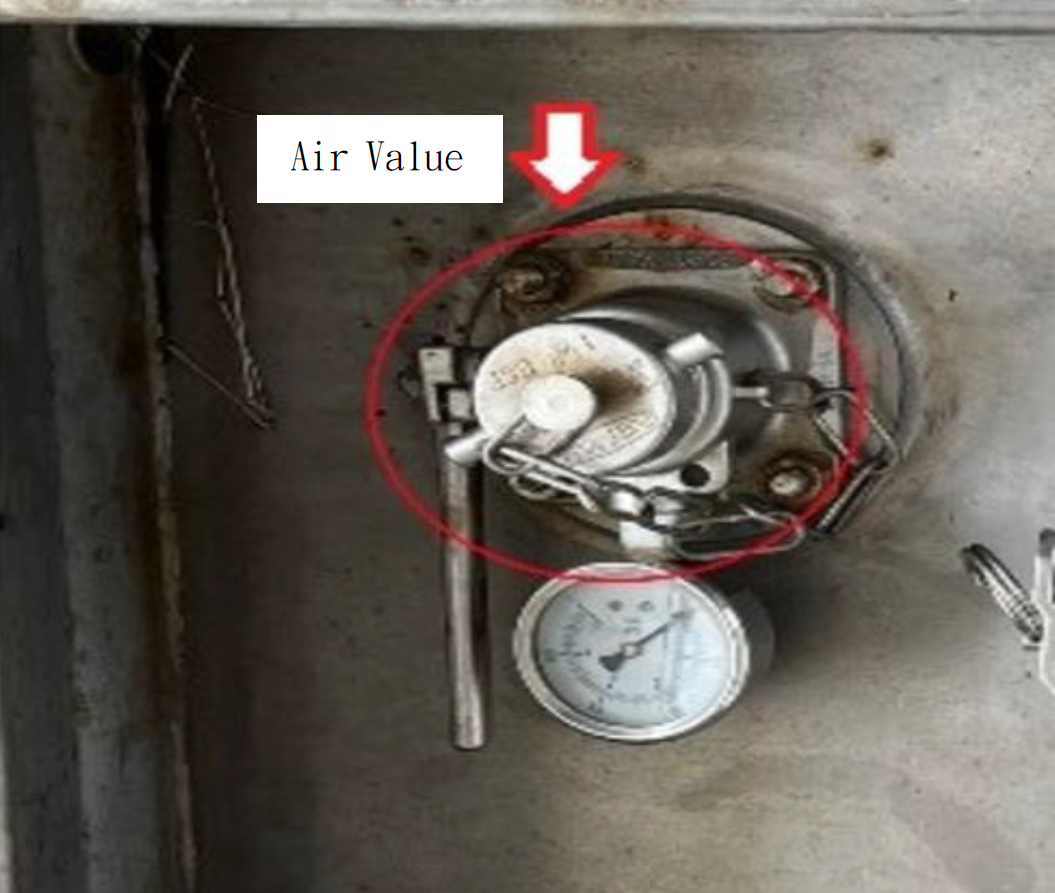

2. ISO TANK T14 Air Valve: Specs and Adapter Installation

The air valve, located on the top of the ISO TANK, is 1.5 inches (DN40). Before injecting air or nitrogen, the cap must be removed, and a pipeline must be connected using the appropriate quick adapter.

(1) Adapter Components

- A-Type Adapter (1.5″ Female Thread) :

- Connects the air valve to a 1.5″ quick coupling

- 1.5″ Quick Coupling :

- B-Type : Male thread

- D-Type : Female thread

- Choose based on the connection type at your facility

1.5″ B-Type Coupling

1.5″ D-Type Coupling

(2) Connection Order

- Air Valve

- A-Type Adapter (1.5″ Female Thread)

- 1.5″ Quick Coupling (B-Type or D-Type)

(3) Key Considerations

- Thread Compatibility : Match the thread types. ISO TANK valves use BSP threads.

- Leak Prevention : Use gaskets and confirm tight connections between adapters and couplings.

- Material : 304 or 316 stainless steel is commonly used, with 316 offering superior corrosion resistance.

- Coupling Sizes : Available in 1/4″, 1/2″, 3/4″, 1″, 2″, 3″, 4″, and 6″.

Published Date : January 24, 2025