What is a Customs Code? A Complete Guide to the Importance of Using the Correct HS Code for Imports and Exports

Meta Description

HS Code is a globally recognized customs classification system crucial for accurate declaration of import and export goods. Learn why using the correct HS Code is essential and how errors can lead to delays or fines in international trade.

Introduction

As global trade continues to diversify, the Harmonized System Code (HS Code) has emerged as a universal classification tool for customs procedures. It improves customs clearance efficiency, prevents trade disputes, and ensures compliance and safety. Understanding the correct use of HS Codes is critical for smooth international shipping, while errors can lead to serious consequences.

1. What Is an HS Code?

An HS Code (Harmonized System Code) is an internationally standardized system for classifying traded products, developed by the World Customs Organization (WCO).

(1) The first six digits of the HS Code are standardized globally.

(2) Additional digits may be added by individual countries for more specific classifications:

- S. and China : 10 digits

- EU countries : 8 or 10 digits

The structure of an HS Code :

- 1st–2nd digits (Chapter): Broad product category

- 3rd–4th digits (Heading): More specific product type

- 5th–6th digits (Subheading): Detailed classification

- In Taiwan:

- 7th–8th : Section

- 9th–10th : Statistical code

- 11th digit : Inspection code

Example :

HS Code for Acrylonitrile (AN) is 2926 1000 005

- 29 : Organic chemical products

- 26 : Cyanides

- 10 : Specific subcategory

2. Why Is It Important to Use the Correct HS Code?

(1) A Global Standard for Product Classification

The HS Code enables global consistency for identifying goods across borders, streamlining trade regulations, taxation, and logistics.

(2) Basis for Import/Export Duties

Different codes have different associated tariffs. Customs officers use the codes to determine the correct tariff rate to apply to imported goods. Using the correct HS Code ensures accurate tax calculation and eligibility for trade incentives or duty exemptions.

(3) Supports Customs Data Collection and Regulation

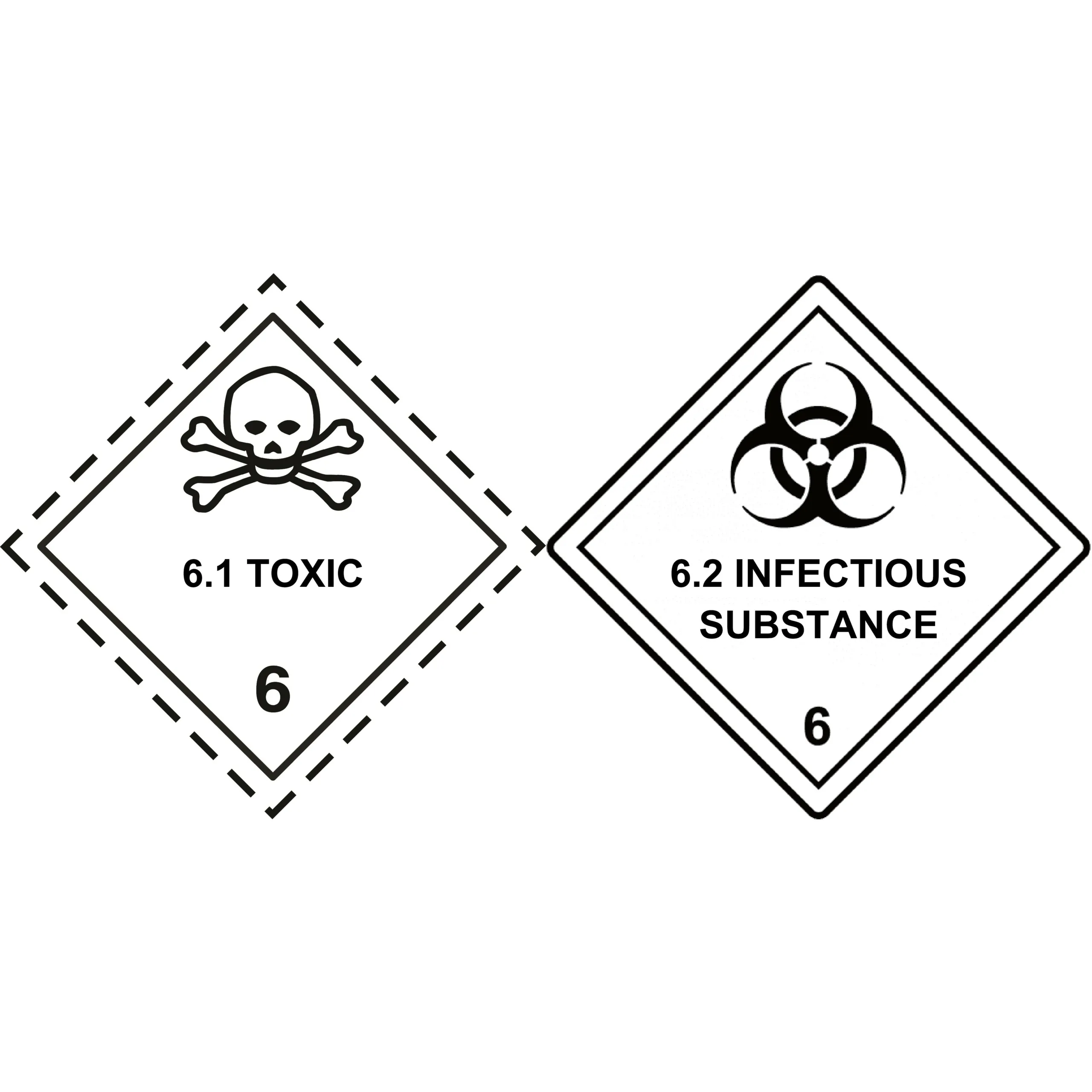

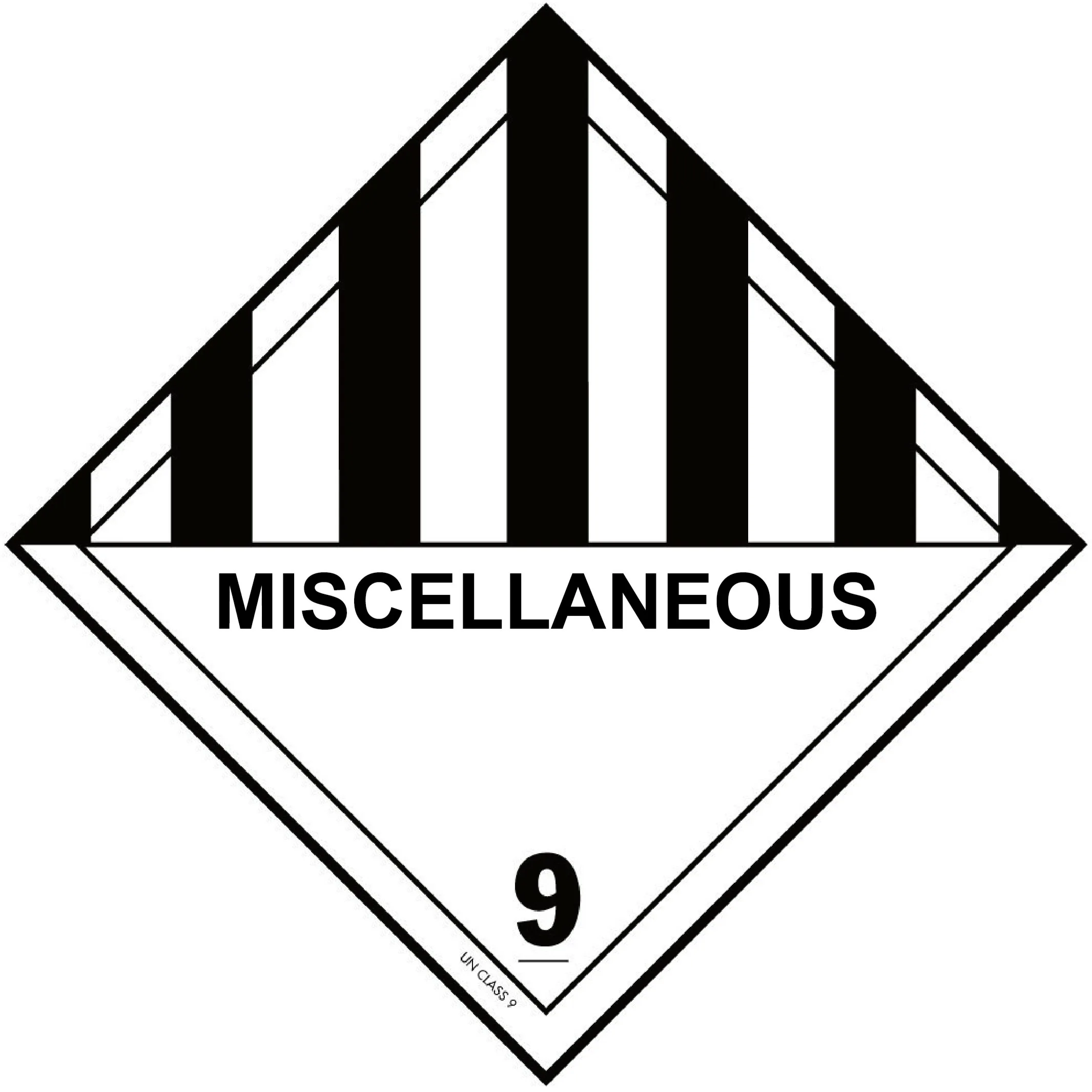

Governments rely on HS Codes to compile trade statistics, formulate economic policies and assess economic performance. They are also used to regulate sensitive, restricted, or hazardous goods in compliance with international and domestic laws.

Further Reading : What Are Dangerous Goods? A Quick Guide to Hazard Classification and Transport Regulations

(4) Increases Shipping Efficiency

Correct HS Codes minimize clearance delays by facilitating faster identification and declaration of goods. Businesses can enjoy smoother logistics and improved trade efficiency.

3. What Happens If the Wrong HS Code Is Used?

(1) Delays or Rejection at Customs

Using an incorrect HS Code can result in delays during the customs clearance process. Customs officers may require amendments or corrections to the code, causing your goods to be held in customs-controlled areas and delaying their arrival at the designated destination. In the worst-case scenario, customs authorities may reject the clearance and deny release of the shipment entirely.

(2) Extra Duties or Penalties

Besides delays or denied release of shipment, mistakes may also incur additional taxes or fines, and may even lead to legal consequences. Thus, double-checking the code before customs declaration is essential.

(3) Added Scrutiny from Customs Authorities

Repeated misuse or suspected intentional evasion may land companies on a customs watchlist, increasing future inspection times and scrutiny. This will pose a problem for future business operations.

(4) Damage to Business Credit & Reputation

Frequent misuse of HS Codes can lead to miscalculated tax rates and potential tariff disputes, which in turn may lower a company’s credit rating. This increases the difficulty and cost of future business operations. Furthermore, customs clearance delays may lead to dissatisfaction among consignees, damaging the company’s reputation and eroding the trust in business partnerships.

Published Date : February 6, 2025